MES Solution for Food and Pharma

Food safety and Quality products are growing property for the world's consumers. To deliver the market requirement, The countries regulatory bodies and manufacturers have to pay closer attention on food production process. FDWare developed Manufacturing solution decade ago to cater future market needs, keeping our focus on latest technology to optimizing the manufacturing process, preventing all possible errors(CCP, NC, OPRP, etc.,) and help the manufacturer to simplify their operation. Fdware has over 15 years of experience providing world class software digital solutions to customers around the globe. Our customers span more than 400+ sites across the Dairy(Milk, Yogurt, Cheese, butter, Milk Powder, Nutritional supplements, IceCream, ..) Beverages (Energy Nutritional Drinks, Corbonated Drinks, Water,...), Food, Cosmetics and pharmaceutical industries. To know more about our solution, please check our Product page.

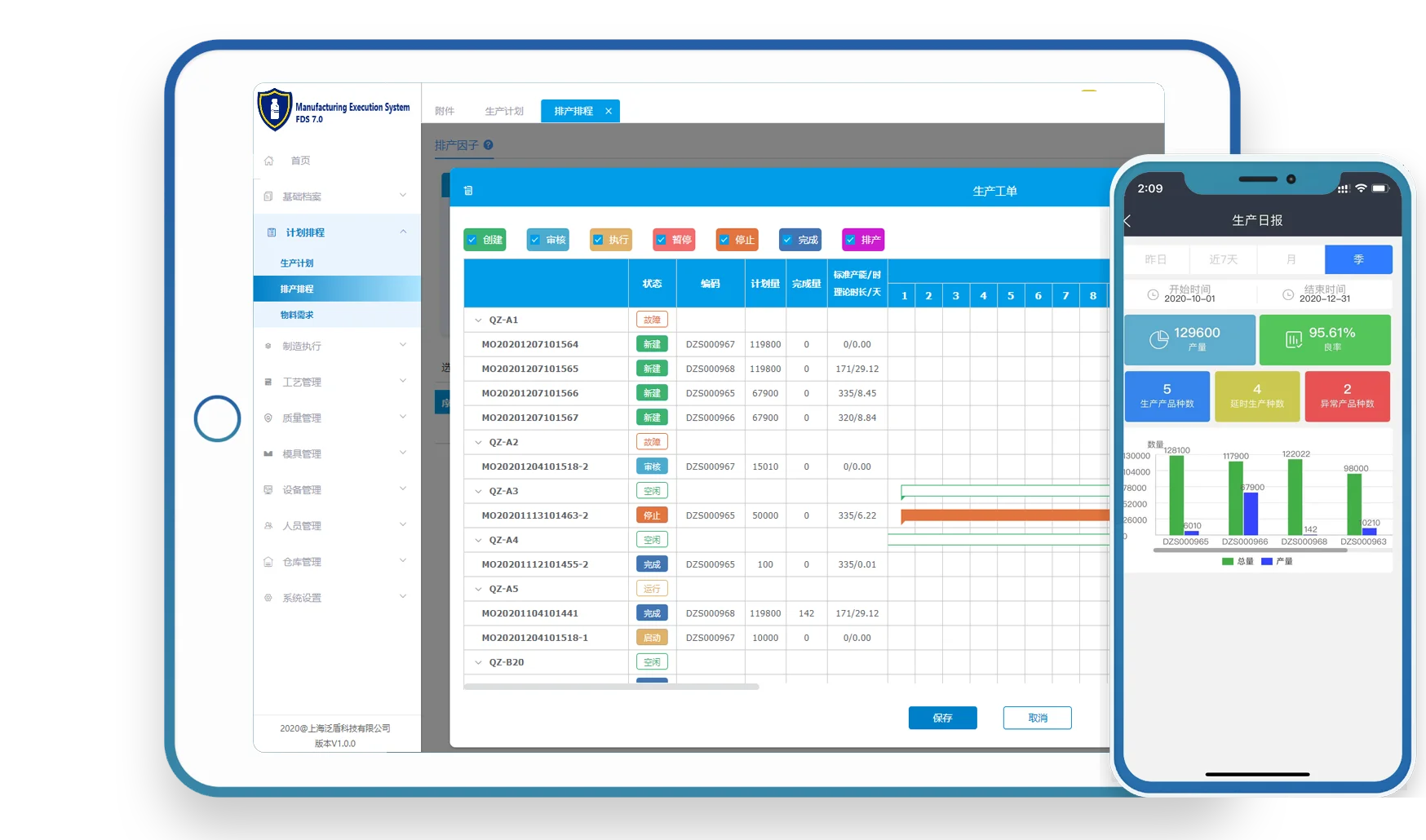

Drive your Production by Recipe

Recipe Drives Execution

Our Recipe drives the execution from Process, steps, seqeunce and much more

Guide the Direction

Our System remind to scan, Scan to proceed, if matches execute the steps

Keep All Records

Everything is recorded from material to operation to trace back when needed

YOSO - You Only Scan Once

In Single Scan or glance we know the integrity of the object(Either Raw Material, Product or a process). We check N number of things behind the scene in just fraction of a second.

Smart Label

Our Smart label support internal and external code comparison, code rule analysis, convenient for the operation to collect and verify. We support Barcode, QR Code and RFID

HighTech Devices

We use hightech devices to collect data electronically in real time, eliminate the risk factors and increase efficiency in all execution process from weighing to feeding

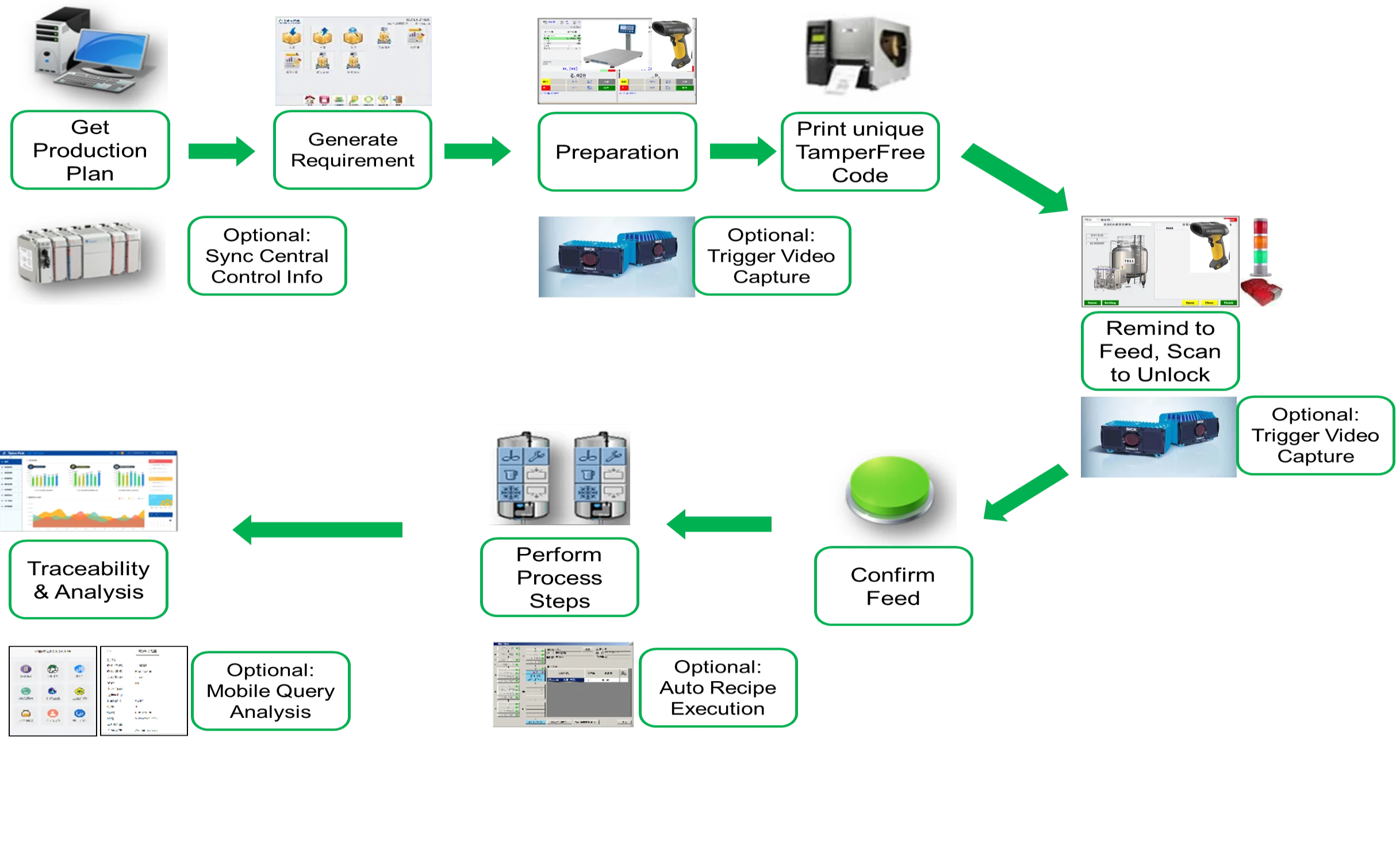

TamperFree Production

Production & Requirement Plan

Creating Production Order is so simple just by selecting Recipe Template and adding required Quantity. System guides you to rest of the steps like split batches by the equipment capacity. Also Recipe can be modified at RunTime based on quality or material availability. System calcualte and generate the requirement by the process and publish for execution

Preparation & Feeding(ChargeIn)

Numerous control measures are applied to prevent allmost all kind of failures in Preapration/Weighing and Feeding(ChargeIn) process. System will only allow to proceed next step when acceptable parameters are met

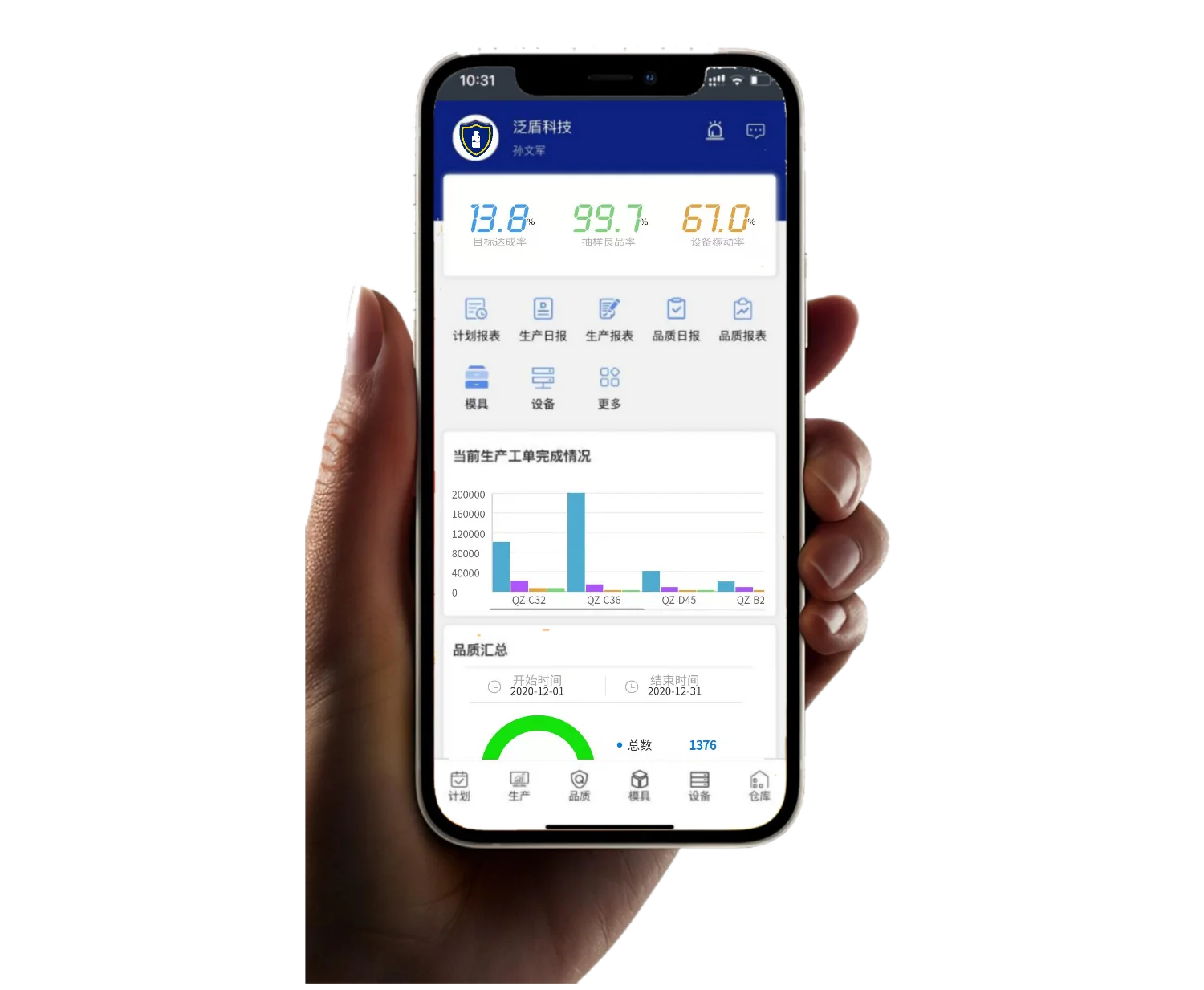

Keep your Plant on your Hand

Complete view of your plant operation in your mobile.Plenty of analysing charts help to take your elegant actions

Charts Analysis

Reports of every process of your plant using latest technology which can be drill down and get to the root, which helps to take right direction of your business

Click Away

All the functions with in your reach. You can customize the screen what you need to focus

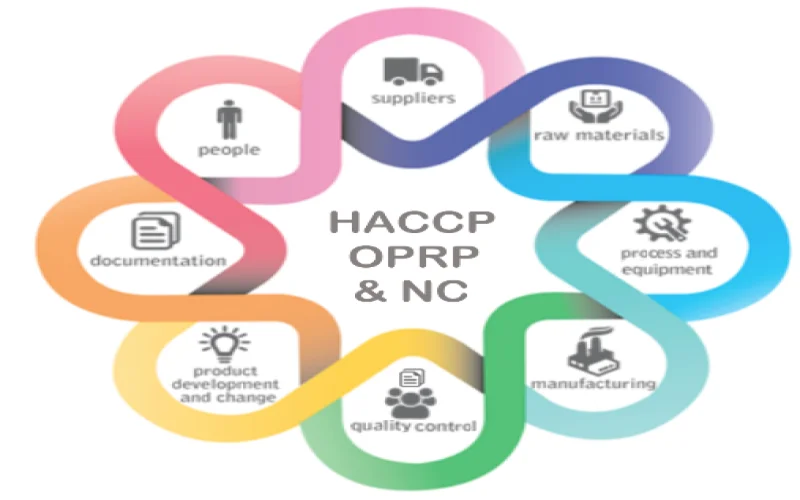

Prevent CCP(HACCP), OPRP & NC Failures

Prevent all possible errors (Identity, Position, Material and Process Errors) in Manufacturing

Control measures applied to prevent or reduce a significant food safety hazard to an acceptable level, and where action criterion and measurement or observation enable effective control of the process and/or product. We execute 'N' number of check behind every operation

Prevent almost everything except intentional🧐⛔️

Paperless Operation

All process and operations are covered in our solution. System records everything digitally and keep securely for future needs and eliminate all paper works.

Save time and Save Earth

System saves your time by eliminating the paper work and increase your operation efficiency. At last but not least we all need to adapt green to save planet for our future

Our Customers

FDWARE

FDWARE