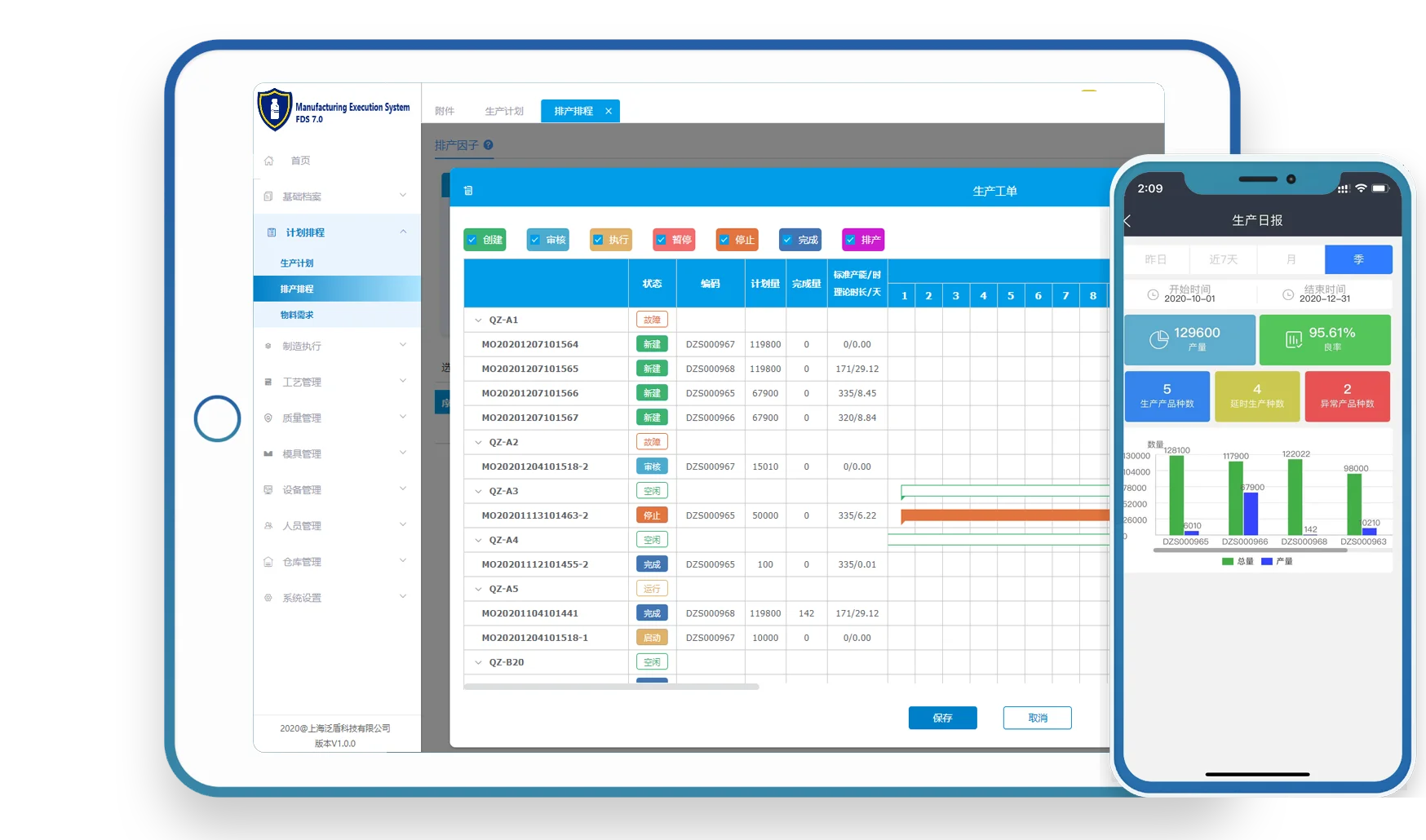

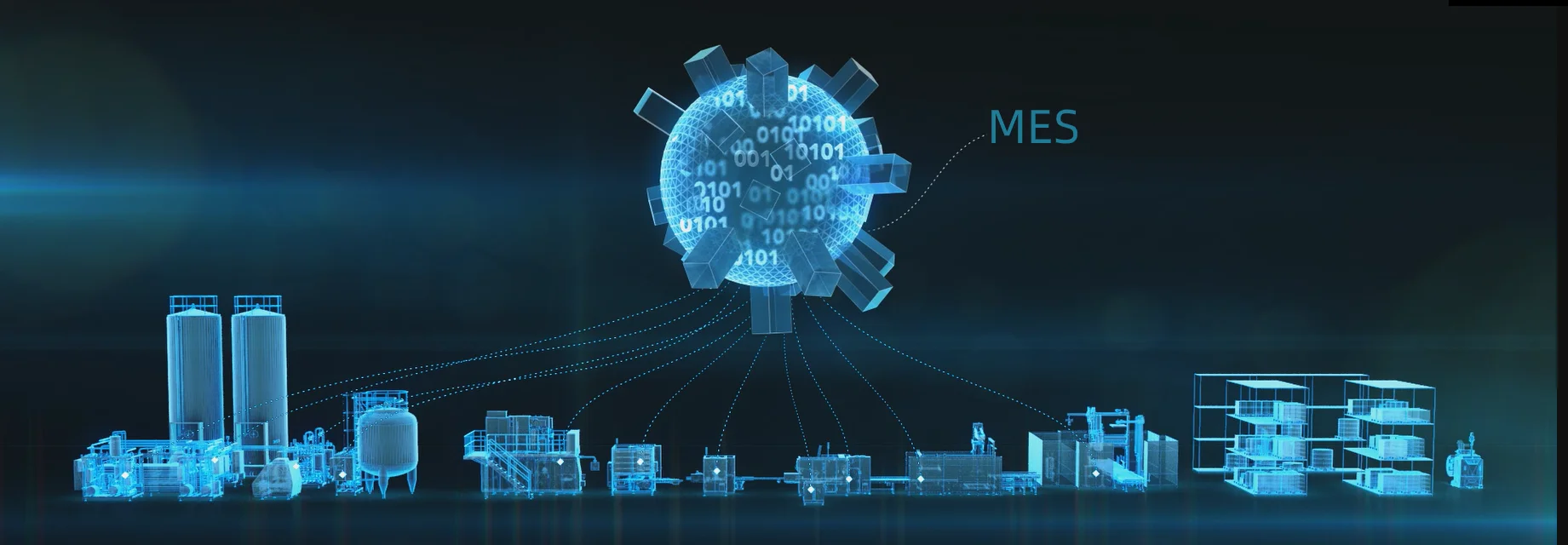

Food and Drugs Manufacturing Execution System FDS 7.0

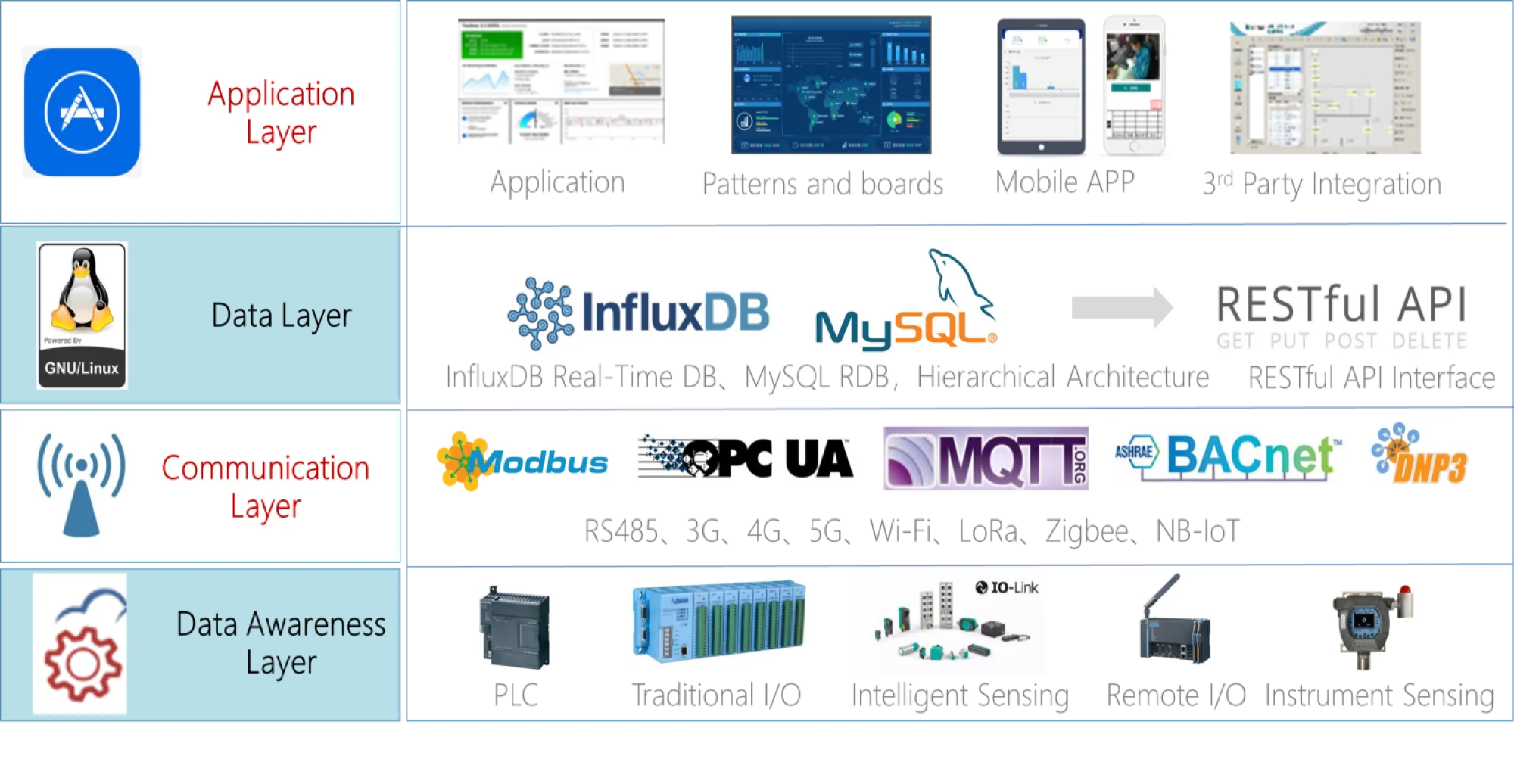

System Structure

Strong Layers

FDS Core Structure covers all layers from Application, Data, Data Awareness & Communication, for Smart Manufacturing Execution

Data Acquisition

Collect and Calculate at one Stop to minimize the Service response.

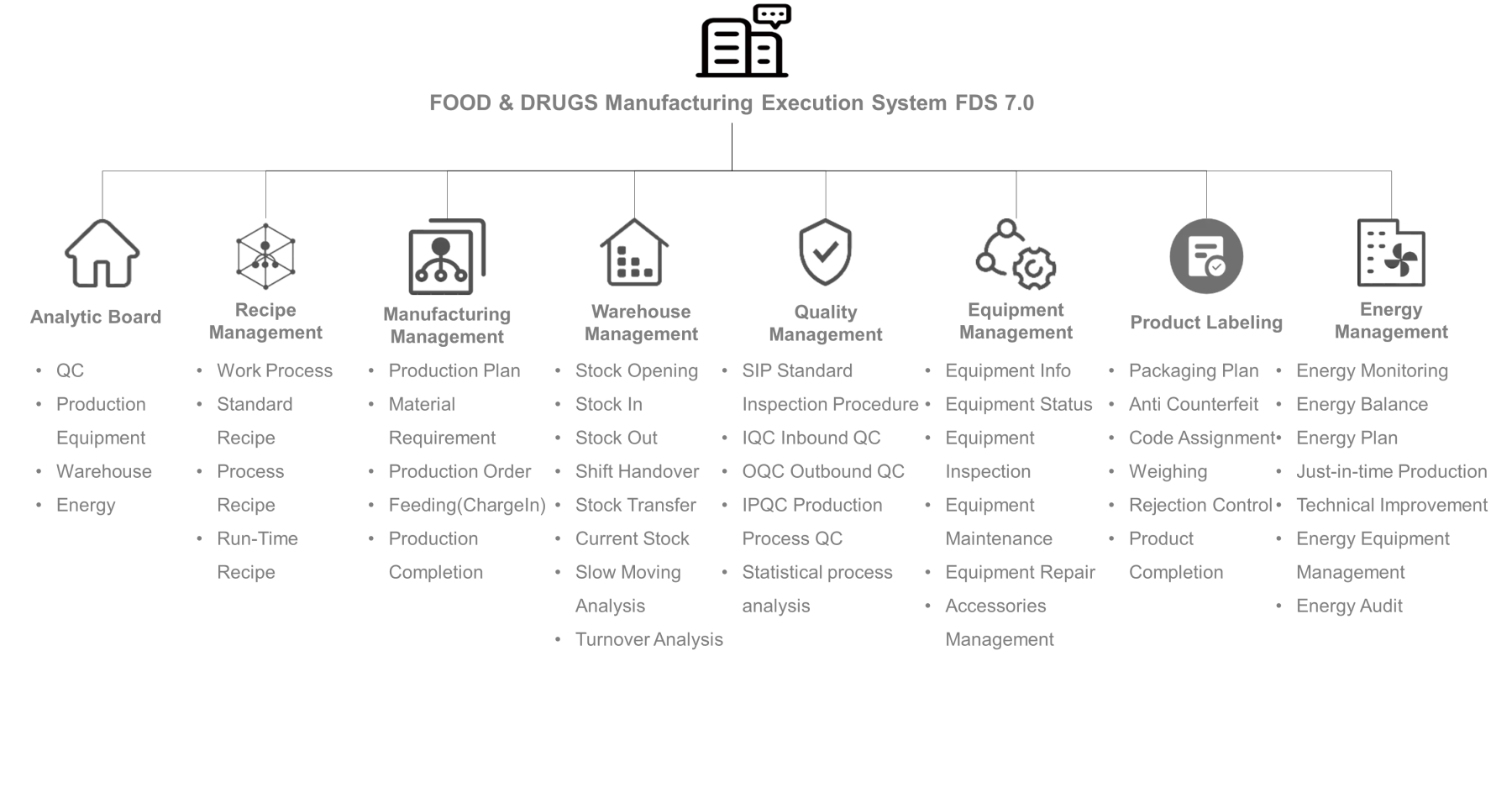

Product Features

All in One place

We know what the industry needs for MES. We have all modules from Inventory, Recipe, Manufacturing, Warehouse, Quality, Equipment, Packaging & Energy.

Smart DashBoards

Numerous dashboards to know whats happening and take action: QC, Production, Warehouse, Equipment & Energy Dashboards

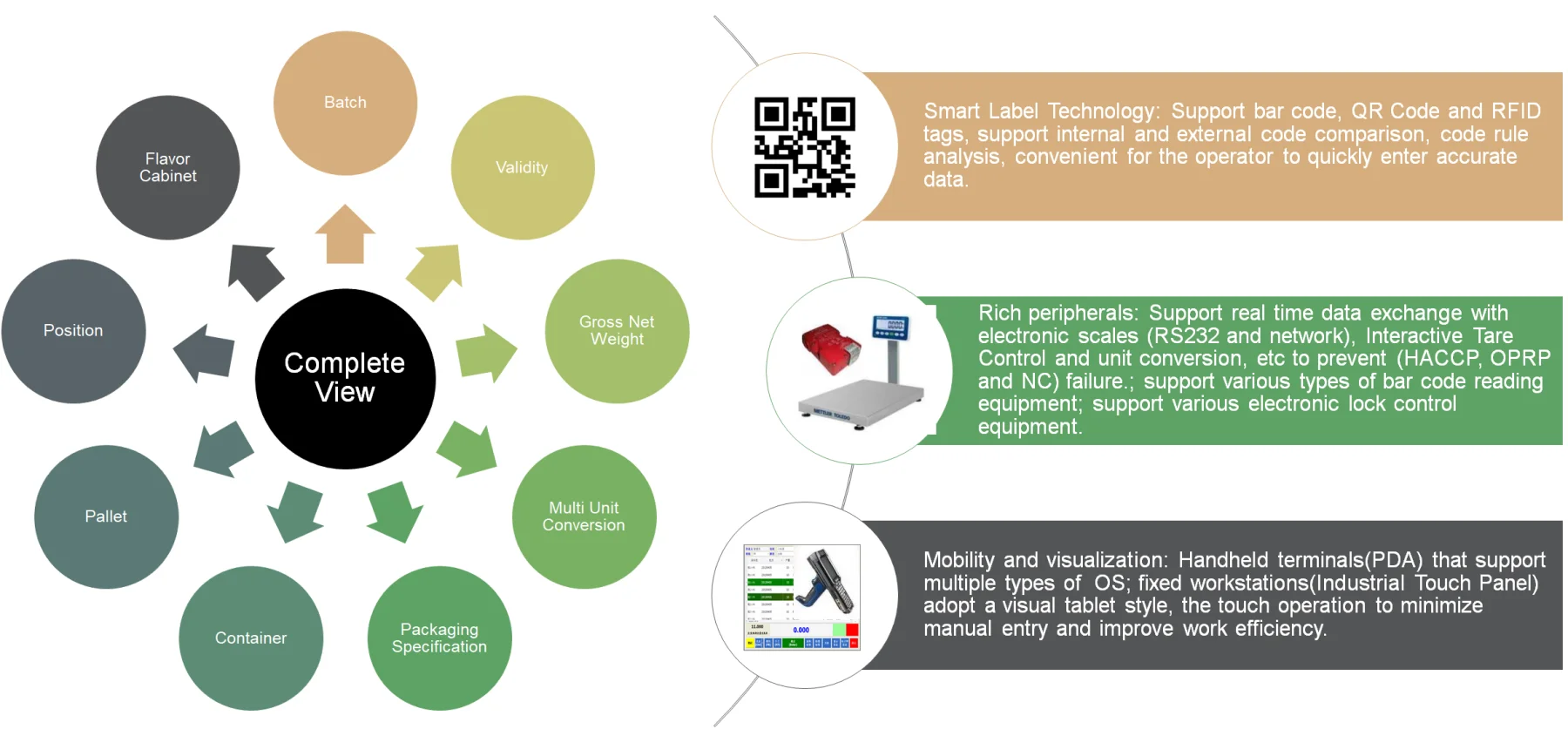

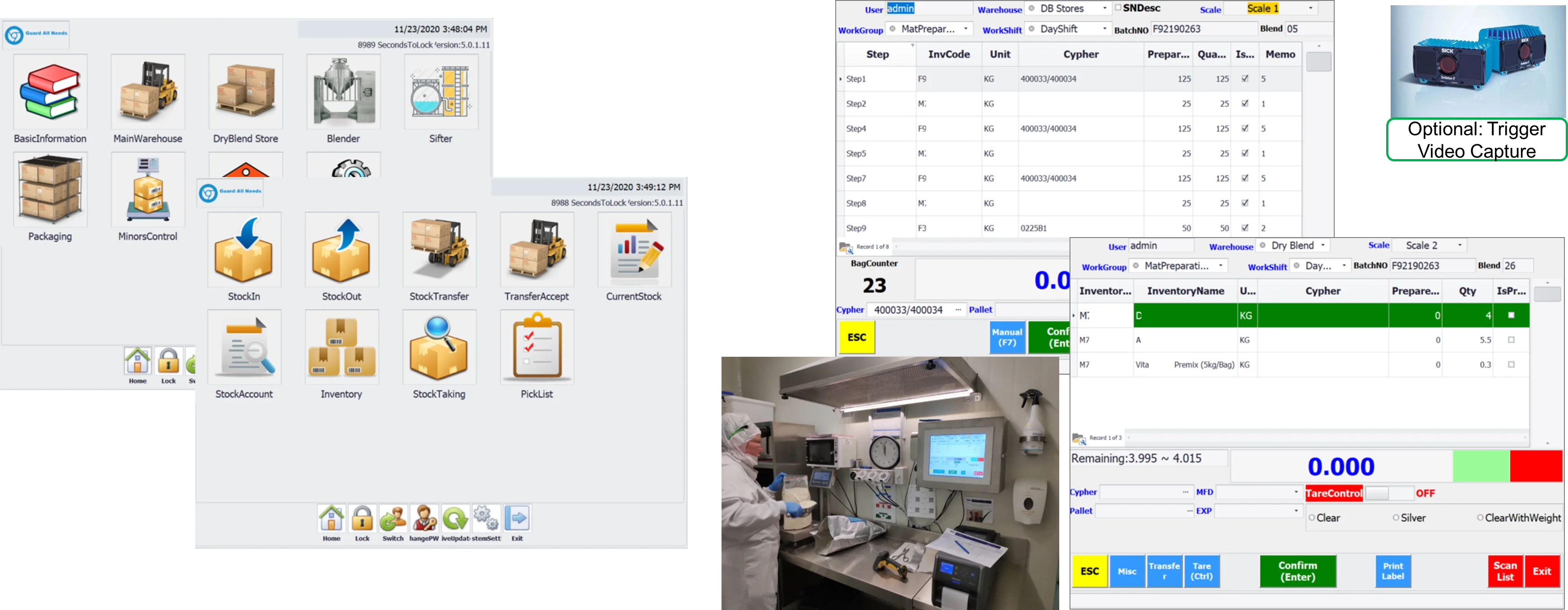

InventoryManagement

Complete Control Measure

All required control measures(Lot, Pallet, Validity, Container, Cabinet, Storage Position, Multi Units, Gross/Net Weight, Packing Spec, much more) are applied to manage your inventory which ensures safety of the product.

RichDevices & Mobility

We use hightech devices to collect data electronically in real time, eliminate the risk factors and increase efficiency in all process

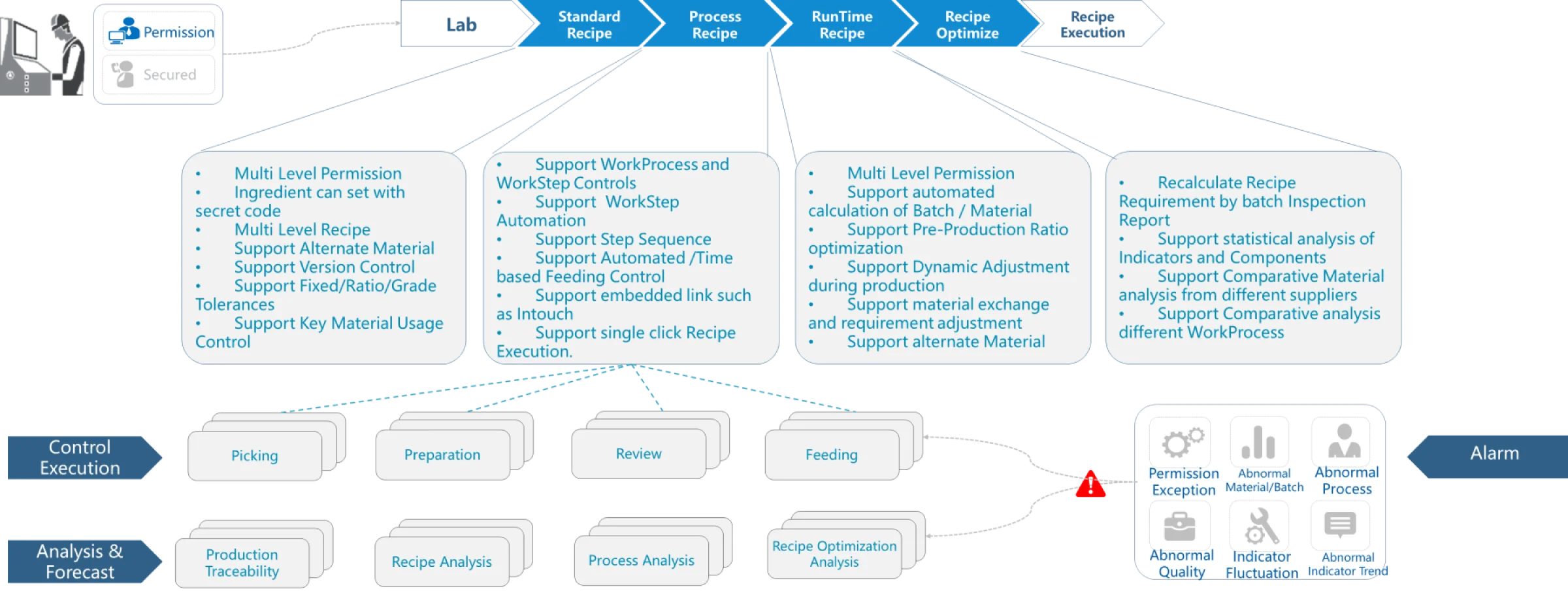

RecipeManagement

Recipe Drives your Execution

We understand Recipe always is core of all process for the product. Our Recipe has the process, steps along with Other requirement to drive the Manufacturing Execution.

Smart & Secured

Support Multi level permissiom, Multi level Recipe, Version Control, Ingredient can set with secret code to hide their info, Fixed/Ratio Tolerances, Key Material usage to pay more attention in Exectuion, Process sequence, step sequnce, Process and Step Control, Work Step Automation, Automated or Time based feeding control, Embeded links to other system such as Intouch and much more.

Dynamic Adjustment

Make adjustment to Recipe at runtime based on production quality, updating the requirement including adding or replacing the ingredient

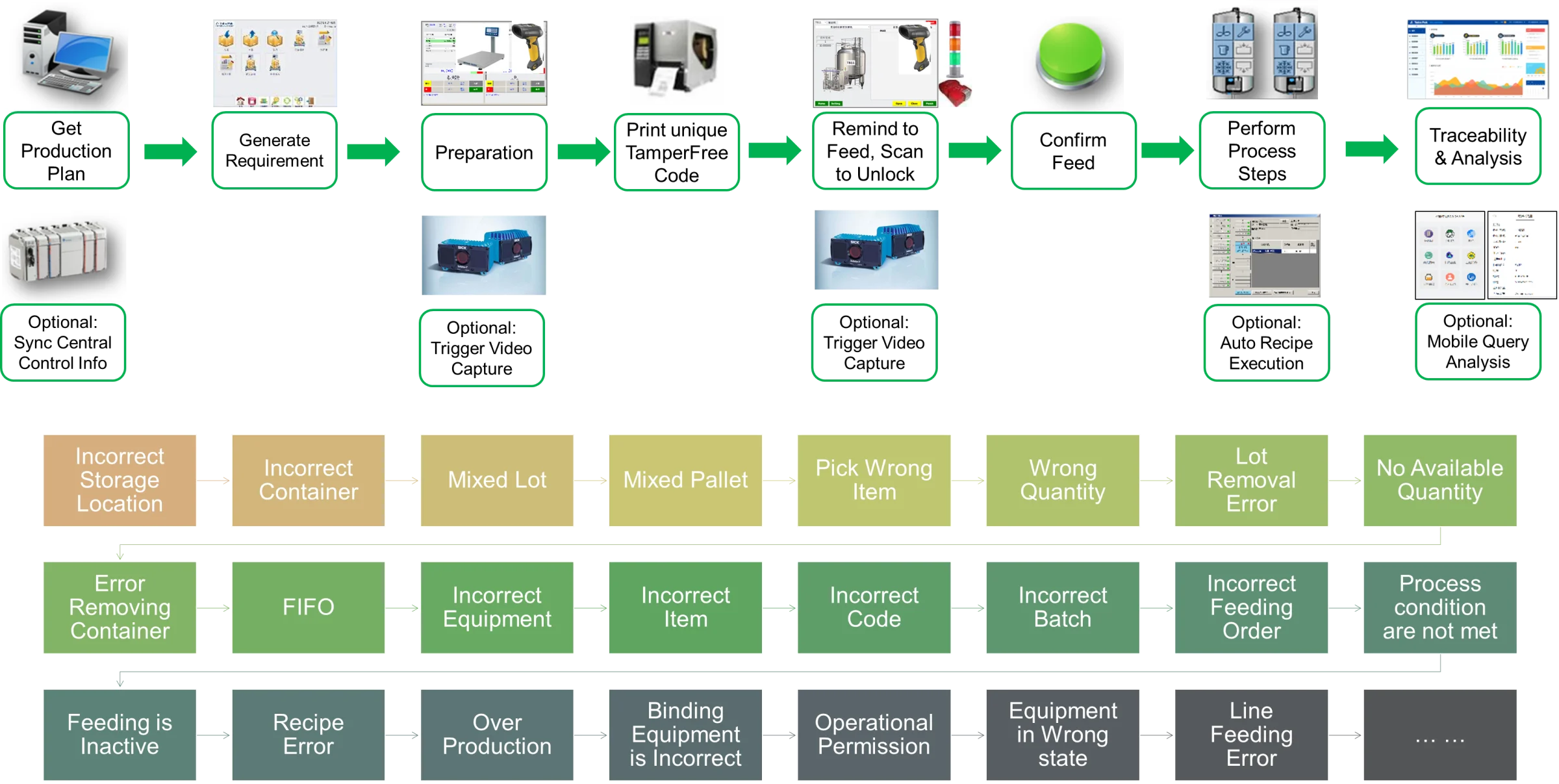

Tamperfree Production

Production & Requirement Plan

Creating Production Order is so simple just by selecting Recipe Template and adding required Quantity. System guide you to split batches by the capacity. If any changes to the Recipe, which can modified at RunTime. System calcualte by required process and generate the Requirement

Preparation & Feeding(ChargeIn)

Numerous control measures are applied to prevent allmost all kind of failures in Preapration/Weighing and Feeding(ChargeIn) process. System will only allow to proceed next step when acceptable parameters are met

Preparation/Weighing

Smart Weighing

Weighing station supports visual guided operation and interactive data with various electronic scales. Support various weighing and preparation modes. Our system also supports parallel weighing.

Multiple Preparation Modes

Our system supports Preparation by Order / Recipe / Material

Intuitive & Interactive

Intuitive to operate, every steps are guided and easier to learn

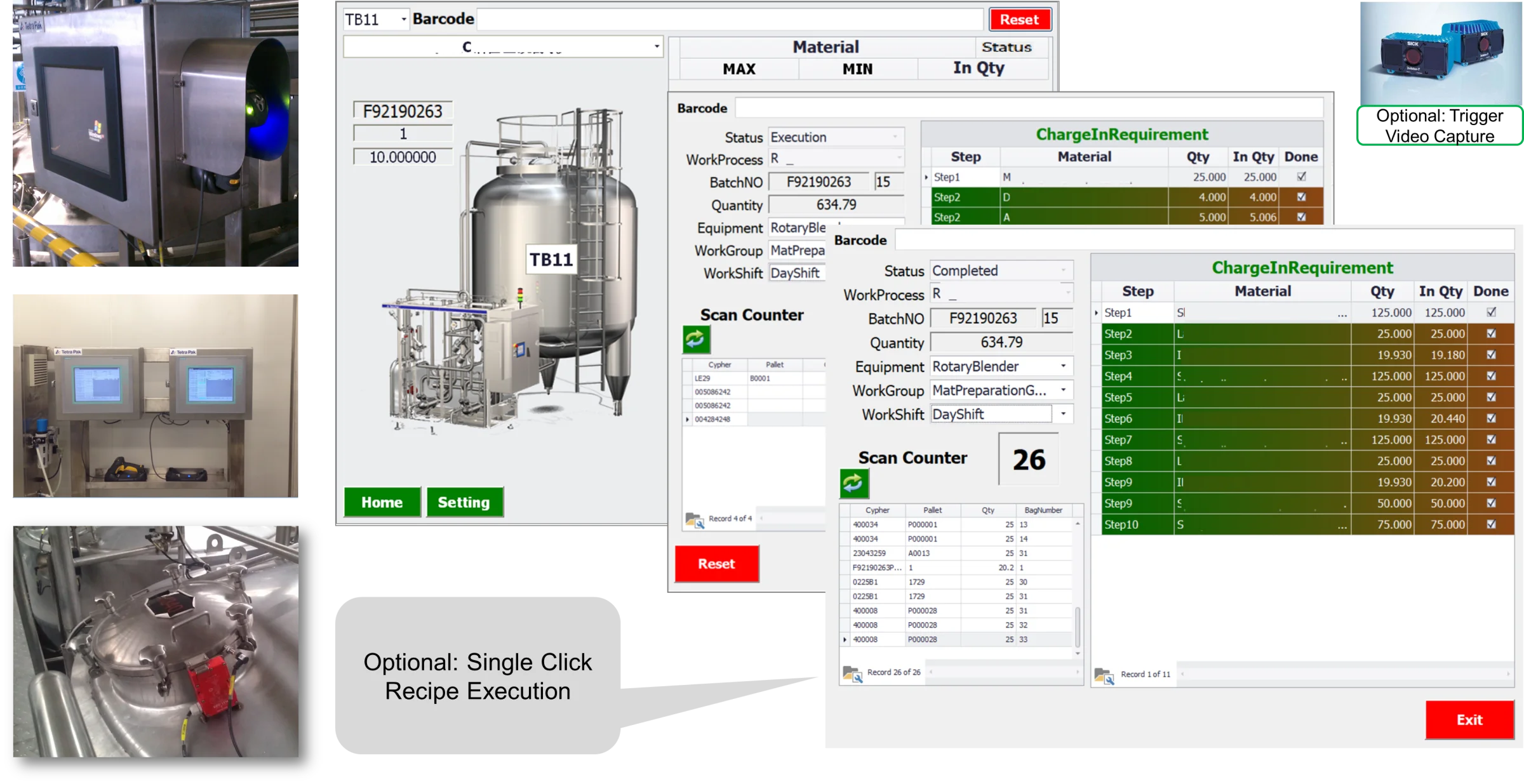

Feeding

Take care all Control Measures

Numerous control measures are applied to prevent allmost all kind of failures in Feeding(ChargeIn) process. System will only allow to proceed the step when acceptable parameters are met, like when ingredient feeding step is ready system allow to scan the ingredient and send signal to open tank lock if any.

Process Automation

System supports Work Step Automation, Automated or Time based feeding control

MobileApp

Complete view of your plant operation in your mobile.Plentty of analysing charts help to take your elegant actions

Charts Analysis

Reports of every process of your plant using latest technology which can be drill down and get to the root, which helps to take right direction of your business

Click Away

All the functions with in your reach. You can customize the screen what you need to focus

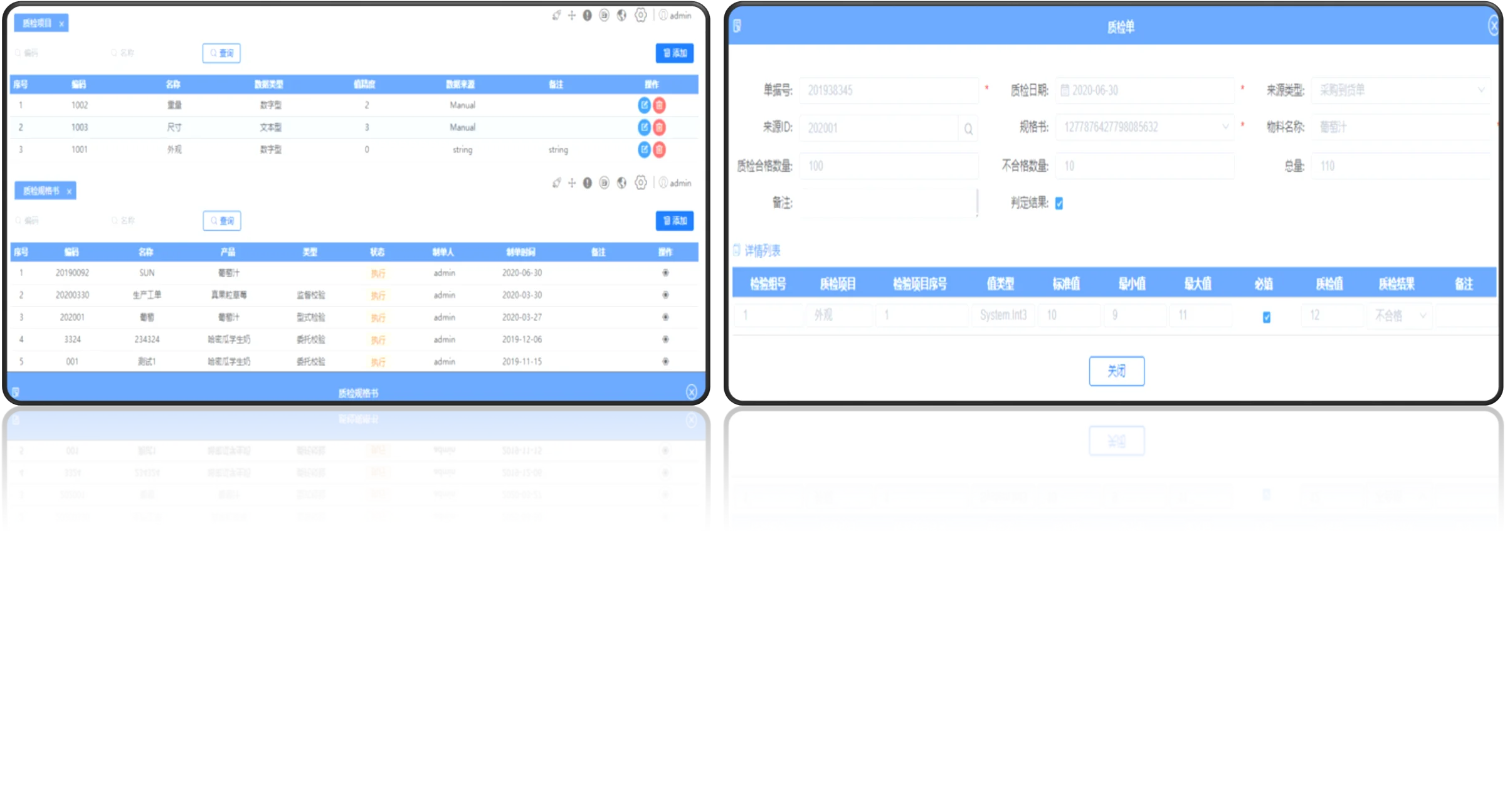

QualityManagement

Have All in one place

Support the Inspection order link with Arrival documents, production documents, completion documents, etc., to achieve incoming material inspection, process inspection, random inspection and finished product inspection.

Support All Stages

Support the Inspection Specification for different materials, products and production stages

Customize Inspection

Support custom configuration of Inspection items.

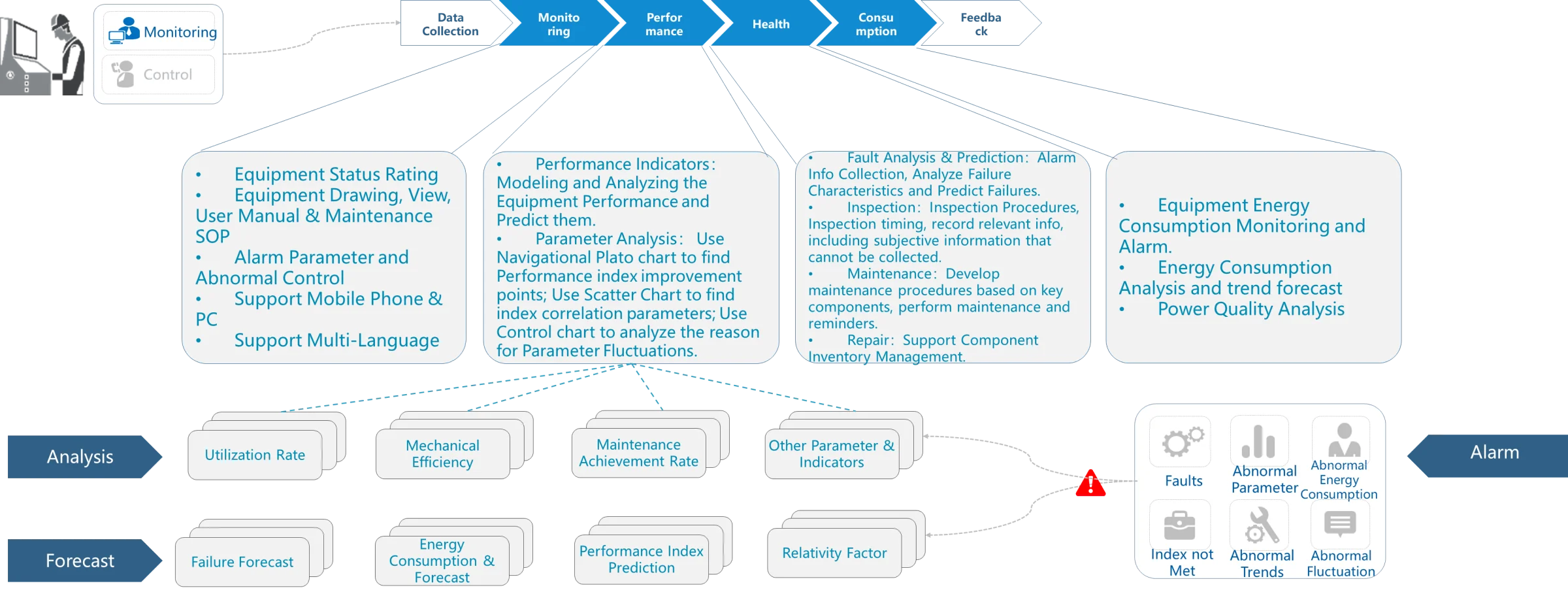

EquipmentManagement

Monitoring

Monitor all your equipments and its performance, Send Alarm when it malfunction

Maintenance Spec and Order

Maintain each Equipment maintenance spec, procedures, schedule, order and consumption of parts

Keep the Record of All

We keep every data from the equipment, interms of energy consumption, efficiency, downtime, Maintenance schdule along with the Equipment drawing, User Manual, Maintenance SOP, etc.,

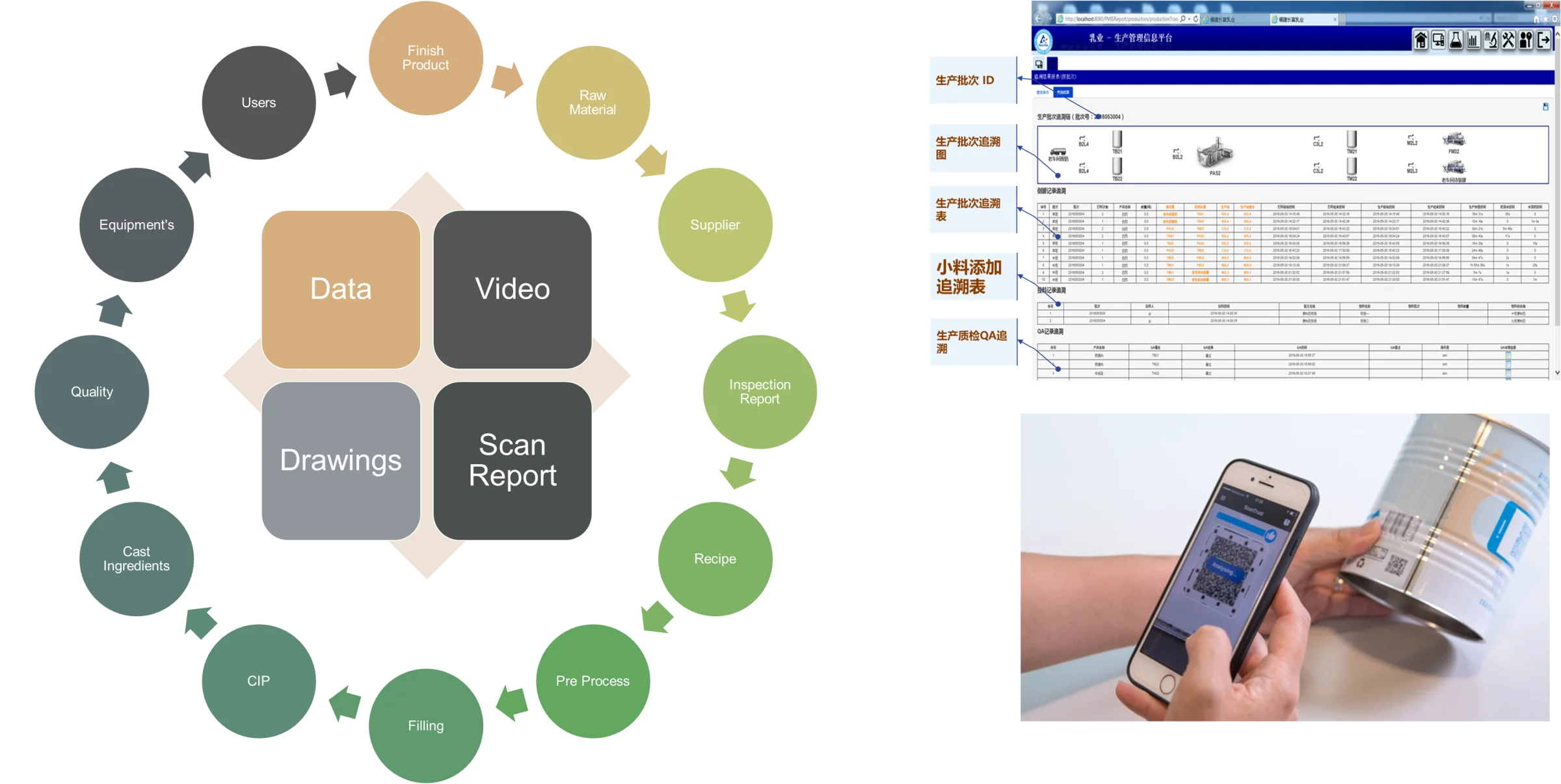

Complete Traceability

Raw Material to Finish Product

Get all the information recorded related to the object either raw material info, manufacturing operation details to finish product packaging details

Forward & Backward

Can track both ways, from Raw material to finish product or finish product to the source(Raw Material).

Code Authenticity

When you traceback something, System start with the code genuiness before finding the details

FDWARE

FDWARE